“This is an exciting first step for Joule in an effort to secure multiple optimal sites for demonstration, both within and beyond the United States, and to ultimately commercialise our process at the scale, costs and productivities that can make a strong impact in the global fuels market,” said Bill Sims, President and CEO of Joule. “In stark contrast to the complex, energy-intensive processes required to produce biofuels from biomass, Joule is forging ahead with a platform for high-volume production of renewable, infrastructure-ready diesel and ethanol at stable, competitive costs. We thank the state and Lea County officials for their tremendous support of this project.”

Lea County ideally meets Joule’s requirements for production, including high solar insolation, access to non-potable water and waste carbon dioxide. In addition, Joule could benefit from $19 million in state incentives to facilitate operations at commercial scale. This includes a tax credit made possible by the Advanced Energy Product Manufacturers Tax Credit Act, which the state legislature voted to amend in recognition of new, breakthrough processes like Joule’s that merit qualification.

“Lea County has long been a supporter of the energy industries, from traditional oil and gas to renewables,” said Lisa Hardison, President and CEO of the Economic Development Corporation of Lea County. “We’re thrilled to welcome Joule and support its breakthrough process, while growing our economy as well as the EnergyPlex.”

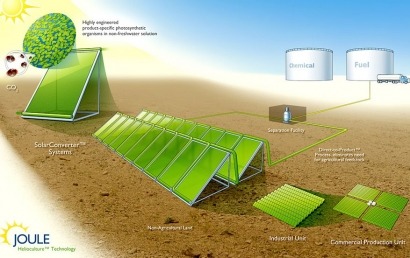

Unlike the energy-intensive, multi-step processes required to produce fuel from algae or other biomass sources, Joule’s Helioculture™ platform produces infrastructure-ready diesel and ethanol directly and continuously from sunlight and waste carbon dioxide, with no dependence on arable land or fresh water. The diesel process yields long-chain alkanes, the majority component of diesel fuel, as opposed to a low-percentage blendstock like biodiesel. As a result it can immediately “drop in” to the existing diesel infrastructure with no need for refining or chemical processing.

Joule’s production facilities will employ the next generation of the company’s novel SolarConverter® system, which manages the direct, continuous process from photon capture to product synthesis and separation with efficiencies that are up to 50X greater than those of biomass-dependent processes. At full-scale production, Joule expects to deliver diesel and ethanol for as little as $20/bble and $0.60/gallon respectively, including current subsidies.

For additional information: