The team, led by Taylor Weiss, a postdoctoral researcher in the Ducat lab at the MSU-Department of Energy Plant Research Laboratory, took cyanobacteria, that use sunlight to naturally produce sugar, and genetically tweaked them to constantly leak that sugar into a surrounding saltwater medium.

They paired them with natural bioplastic-producing bacteria that fed on the leaked sugar.

Processed biomass contained a near constant 30 percent bioplastic content, four times more than similar experimental systems, and production rates were over 20 times faster.

The approach avoids fossil fuels for production and aims to reduce plastic’s impact on the environment.

“A major problem is that most synthetic plastic today is not completely biodegradable, so it lasts for hundreds of years after being discarded, in landfills and in water ecosystems,” Weiss said.

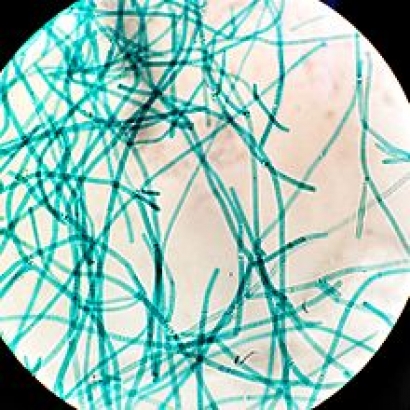

Scientists are looking to genetically alter cyanobacteria, tiny photosynthetic workhorses, also known as blue-green algae, to funnel their outputs into useful products.

Weiss said that scientists create gradually more efficient bio-production systems all the time, but a major twist is that his improves over time, without human meddling.

“The cyanobacteria constantly make sugar through photosynthesis, and the bacteria constantly beef up on it, which encourages the cyanobacteria to keep producing,” Weiss said. “So, the system continuously evolves in a virtuous cycle.”

Looking forward, Weiss wants to partner cyanobacteria with other specialist bacteria to create cheap, environmentally friendly bioproducts, like biofuels to power jets and cars, fragrances, edible dyes and medicines.

“Ultimately, we aren’t just creating alternatives to synthetic products,” Weiss said. “We’re trying to ask nature to do what it does best: figure out the problem for us.”

Photo: Wikipedia