Isobutanol, like ethanol, is an alcohol, but its lower water solubility and higher energy density have created interest in the compound’s potential use as a gasoline additive or replacement. But manufacturing isobutanol, which is typically produced using biotechnology, has proven difficult and costly.

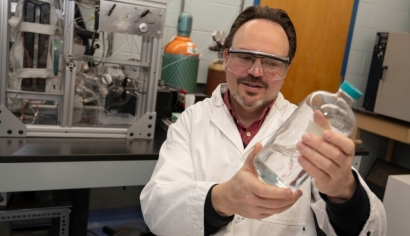

“With the growing threat of climate change and our dependence on fossil fuels and petroleum-producing countries, there is increasing interest in using isobutanol as a gasoline additive in place of ethanol, which can significantly lower a vehicle’s fuel efficiency,” said Michael Timko, Associate Professor of Chemical Engineering at WPI. “But we haven’t found an environmentally friendly, efficient, or inexpensive way to produce it.”

In a paper published recently in Nature Communications (Engineered Microbial Biofuel Production and Recovery Under Supercritical Carbon Dioxide), Timko and colleagues describe a method for producing and extracting isobutanol using supercritical carbon dioxide as a solvent and a bacterium that can thrive in this liquid. The team genetically engineered the bacterium by adding genes for the production of isobutanol. They then showed how supercritical carbon dioxide could overcome two important problems that plague conventional biofuel production methods: low yields and bacterial contamination.

Timko analyzed the process and showed the biofuel could be made using five times less energy compared to traditional manufacturing processes, making it less expensive, more efficient and more environmentally friendly.

Timko co-authored the paper with Kristala Jones Prather, Professor of Chemical Engineering at MIT, and Janelle R. Thompson, Associate Director of the Singapore-MIT Alliance for Research and Technology, who have worked with him on the project since 2015, when they collectively received a $1.5 million award from the Department of Energy. WPI received $500,000 of that grant for Timko’s work on process modeling, biofuel extraction, and process analysis. The MIT team worked on microbiology and genetic engineering.

Isobutanol is made in a bioreactor by fermenting biomass using microorganisms. The final product is extracted with organic solvents, which are often flammable, toxic, and costly. The WPI research team replaced the organic solvents with supercritical carbon dioxide, which is a fluid state of the gas held at or above its critical temperature and pressure.

Timko showed that by using this abundant and renewable solvent, they were able to extract high-purity isobutanol quickly enough to prevent it reaching levels that might otherwise have brought fermentation to a grinding halt. Timko’s analysis shows the supercritical carbon dioxide process consumes about six times less energy than any other extraction process.

The bacteria typically used to produce isobutanol cannot grow in supercritical carbon dioxide, so the team looked for a microorganism that had evolved to thrive in this harsh liquid. They found a good candidate in Bacillus megaterium SR7. Not only can SR7 survive the harsh bioreactor conditions, it is able to grow under conditions that are lethal to all previously studied microbes.

The microbe, though, lacked the genes needed to produce isobutanol, so the MIT team had to add them through genetic engineering. Tests showed that modified Bacillus megaterium SR7 can, indeed, produced isobutanol while growing in supercritical carbon dioxide.

Timko’s team performed calculations on the complete process for growing the organism, producing isobutanol, extracting it from the fermentation mixture, and recovering it so it can be used as a fuel.

“We used 30 years' worth of scientific experience to build this process,” he said. “Just having an organism that can grow in supercritical carbon dioxide isn’t much of a splash but producing isobutanol and being able to siphon it off at the right rate—all together that’s a big, big splash.”