“This is a subclass of fuels that has very specific requirements in terms of the chemistry and the physical properties of the fuel, because you can’t risk something going wrong in an airplane engine,” says Yuriy Román-Leshkov, the Robert T. Haslam Professor of Chemical Engineering at Massachusetts Institute of Technology.

Aviation fuel is a combination of two large classes of chemical compounds. Some 75 to 90% of it is made up of “aliphatic” molecules, which consist of long chains of carbon atoms linked together. “This is similar to what we would find in diesel fuels, so it’s a classic hydrocarbon that is out there,” explains Román-Leshkov. The remaining 10 to 25% consists of “aromatic” molecules, each of which includes at least one ring made up of six connected carbon atoms.

In aviation fuels, some aromatic molecules must remain because they set the necessary physical and combustion properties of the overall mixture. They also perform one more critical task: They ensure that seals between various components in the aircraft’s fuel system are tight.

“The aromatics get absorbed by the plastic seals and make them swell,” explains Román-Leshkov. “If for some reason the fuel changes, so can the seals, and that’s very dangerous.”

As a result, aromatics are a necessary component — but they’re also a stumbling block in the move to create SAFs. Companies know how to make the aliphatic fraction from inedible parts of plants and other renewables, but they haven’t yet developed an approved method of generating the aromatic fraction from sustainable sources.

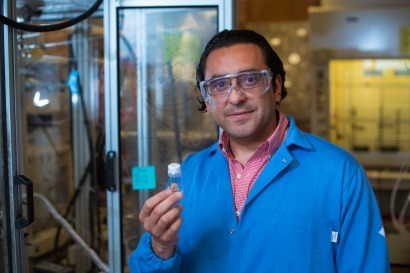

For the past five years, understanding and solving the SAF problem has been the goal of research by Román-Leshkov and his MIT team — Michael L. Stone PhD ’21, Matthew S. Webber, and others — as well as their collaborators at Washington State University, the National Renewable Energy Laboratory (NREL), and the Pacific Northwest National Laboratory.

Their work has focused on lignin, a tough material that gives plants structural support and protection against microbes and fungi. About 30% of the carbon in biomass is in lignin, yet when ethanol is generated from biomass, the lignin is left behind as a waste product.

"Every year millions of tons of waste lignin are burned as a low-grade fuel, used as fertilizer, or simply thrown away," Román-Leshkov said.

The key to converting lignin into the aromatic fraction of SAF is to break the "macromolecule" into smaller pieces while in the process getting rid of all of the oxygen atoms.

Most industrial processes begin with a chemical reaction that prevents the subsequent upgrading of lignin: As the lignin is extracted from the biomass, the aromatic molecules in it react with one another, linking together to form strong networks that won’t react further. As a result, the lignin is no longer useful for making aviation fuels.

To avoid that outcome, Román-Leshkov and his team utilize another approach: They use a catalyst to induce a chemical reaction that wouldn’t normally occur during extraction. By reacting the biomass in the presence of a ruthenium-based catalyst, they are able to remove the lignin from the biomass and produce a black liquid called lignin oil. That product is chemically stable, meaning that the aromatic molecules in it will no longer react with one another.

After successfully breaking the original lignin macromolecule, the team then needed to find a way to remove the oxygen atoms. They needed to selectively break the carbon-oxygen bonds to free the oxygen atoms; they needed to avoid incorporating noncarbon atoms into the aromatic rings (for example, atoms from the hydrogen gas that must be present for all of the chemical transformations to occur); and they needed to preserve the carbon backbone of the molecule — that is, the series of linked carbon atoms that connect the aromatic rings that remain.

Ultimately, Román-Leshkov and his team found a special ingredient that would do the trick: a molybdenum carbide catalyst.

To test their approach in the lab, the researchers first designed and built a specialized “trickle-bed” reactor, a type of chemical reactor in which both liquids and gases flow downward through a packed bed of catalyst particles. They then obtained biomass from a poplar, a type of tree known as an “energy crop” because it grows quickly and doesn’t require a lot of fertilizer.

Based on a series of experiments involving lignin oil from poplar biomass, the researchers determined the operating conditions yielding the best outcome: 350 degrees Celsius in the first step and 375 C in the second step. Under those optimized conditions, the mixture that forms is dominated by the targeted aromatic products, with the remainder consisting of small amounts of other jet-fuel aliphatic molecules and some remaining oxygen-containing molecules. The catalyst remains stable while generating more than 87% (by weight) of aromatic molecules.

To check their products, Román-Leshkov and his team send samples to Washington State University, where a team operates a combustion lab devoted to testing fuels. Results from initial testing of the composition and properties of the samples have been encouraging. Based on the composition and published prescreening tools and procedures, the researchers have made initial property predictions for their samples, and they looked good. For example, the freezing point, viscosity, and threshold sooting index are predicted to be lower than the values for conventional aviation aromatics.

The researchers are continuing to study how their sample blends behave at different temperatures and, in particular, how well they perform that key task: soaking into and swelling the seals inside jet engines.

In addition, he and his team are working with their NREL collaborators to scale up their methods. NREL has much larger reactors and other infrastructure needed to produce large quantities of the new sustainable blend. Based on the promising results thus far, the team wants to be prepared for the further testing required for the certification of jet fuels. In addition to testing samples of the fuel, the full certification procedure calls for demonstrating its behavior in an operating engine — “not while flying, but in a lab,” clarifies Román-Leshkov.

Román-Leshkov and his colleagues are now exploring the use of their approach with other types of biomass, including pine, switchgrass, and corn stover (the leaves, stalks, and cobs left after corn is harvested). But their results with poplar biomass are promising. If further testing confirms that their aromatic products can replace the aromatics now in jet fuel, “the blending wall could disappear,” says Román-Leshkov. “We’ll have a means of producing all the components in aviation fuel from renewable material, potentially leading to aircraft fuel that’s 100% sustainable.”

This research was initially funded by the Center for Bioenergy Innovation, a U.S. Department of Energy (DOE) Research Center supported by the Office of Biological and Environmental Research in the DOE Office of Science. More recent funding came from the DOE Bioenergy Technologies Office and from Eni S.p.A. through the MIT Energy Initiative. Michael L. Stone PhD ’21 is now a postdoc in chemical engineering at Stanford University. Matthew S. Webber is a graduate student in the Román-Leshkov group, now on leave for an internship at the National Renewable Energy Laboratory.

(This article appears in the Spring 2023 issue of Energy Futures, the magazine of the MIT Energy Initiative.)