WM2500 and WV250 engaged many employees at Wright, multiple contractors, and dozens of leading suppliers, partners, and sub-assembly shops, all pushing limits at multiple levels. For example, precision machining meant that the company had to use a particular device of which there were only five in the entire United States.

Both the inverter and motor have been developed in part through the ARPA-E ASCEND programme.

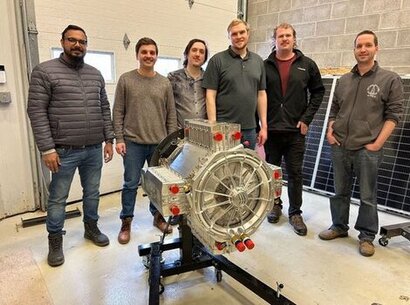

Getting the two to work together required unit testing each system individually, linking the motor and inverter with hundreds of connection-points, and fine-tuning the firmware. This was a multi-year, multi-disciplinary effort, with the next steps being higher power testing, altitude chamber testing at NASA’s Electric Aircraft Testbed, thrust testing, and aircraft testing.

One of the key purposes of US research agencies like DoE’s ARPA-E and NASA is to set visionary challenges and then fund US companies to solve them. As companies like Wright develop technologies to meet these goals, not only does the US get to kickstart entire new industries like electric aviation, but these efforts train thousands of engineers on how to be the best in the world. This is great for aerospace, and it’s also great for US industry.

For additional information: