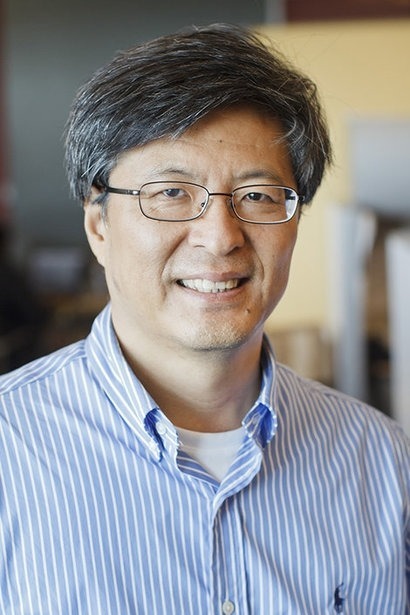

Dr Cho is professor of materials science and engineering in the university’s Erik Jonsson School of Engineering and Computer Science. He has discovered a number of new catalyst materials for lithium-air batteries that can jumpstart efforts to expand batter capacity.

Lithium-air (lithium-oxygen) batteries ‘breathe’ oxygen from the air in order to power the chemical reactions that release electricity, rather than storing an oxidiser internally as lithium-ion batteries do. This means they can boast an energy density comparable to gasoline, with theoretical energy densities as much as 10 times that of current lithium-ion batteries. This in turn gives them tremendous potential for storage of renewable energy, particularly with regard to applications such as mobile devices and electric cars. At one-fifth the cost and weight of those presently on the market, a lithium-air battery would allow an electric car to drive 400 miles on a single charge and a mobile phone to last a week without recharging.

“There's huge promise in lithium-air batteries” said Dr Cho. “However, despite the aggressive research being done by groups all over the world, those promises are not being delivered in real life. So this is very exciting progress. Yongping Zheng [a UT Dallas graduate student] and our collaboration team have demonstrated that this problem can be solved. Hopefully, this discovery will revitalize research in this area and create momentum for further development.”

Practical attempts to increase lithium-air battery capacity have not yielded great results thus far, despite efforts from major corporations and universities. Attempts to do so have resulted in low efficiency and poor rate performance, instability and unwanted chemical reactions. Cho and Zheng have introduced new research that focuses on the electrolyte catalysts inside the battery, which, when combined with oxygen, create chemical reactions that create battery capacity. Soluble-type catalysts possess significant advantages over conventional solid catalysts, generally exhibiting much higher efficiency.

In particular, they found that only certain organic materials can be utilized as a soluble catalyst. The two researchers have now collaborated with researchers at Seoul National University to create a new catalyst for the lithium-air battery called dimethylphenazine, which possesses higher stability and increased voltage efficiency. Cho believes that the research could open the door to additional advances in technology, although this could take five to ten years before the research enables new batteries, that can be used in consumer devices and electric vehicles, to appear on the market.

The research was published in the journal Nature Energy. Co-authors on the study included researchers led by Dr. Kisuk Kang at Seoul National University. The research was funded by Hyundai Motor Company and National Research Foundation of Korea.

For additional information:

UT Dallas Erik Jonsson School of Engineering and Computer Science