At the end of 2010, the global installed power generating capacity of geothermal power plants was more than 11 gigawatts (GW). The US currently leads the world with an installed geothermal capacity of 3.1 GW, followed by the Philippines with an installed geothermal capacity of approximately 1.9 GW, and Indonesia with 1.2 GW.

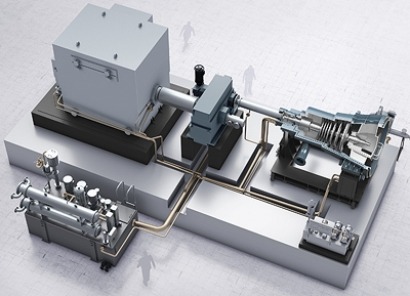

There also exists the potential for the utilization of geothermal energy for power generation in East Africa, Central America, Chile, Russia, Italy, Iceland and Turkey. Based on a study conducted by IHS Emerging Energy Research, the installed capacity of geothermal power is predicted to nearly triple worldwide to approximately 31 GW by 2020. Against this backdrop, Siemens Energy has been working to develop a new steam turbine that can be used in geothermal power plants, which it has launched this month in San Diego. With a rating of up to 60 megawatts, the new SST-400 GEO steam turbine for geothermal applications combines the proven casing and turbine-generator package (gearbox, generator and base frame) of the Siemens SST-400 steam turbine with the steam path technologies developed, tested and applied by the steam turbine service provider TurboCare.

“We’ve done intensive groundwork on the specific requirements of geothermal plants and are now going to market with a proven turbine concept,” said Markus Tacke, CEO of the Industrial Power Business Unit of Siemens Energy. “Worldwide a pronounced increase in the demand for geothermal steam turbines is evident. As a steam turbine manufacturer we are optimally set up with this machine to be well positioned in the marketplace over the long term.”

The sites for geothermal plants vary significantly in terms of thermal fluid mass flow, temperature, pressure, pH and the fraction of minerals and gases such as hydrogen sulphide in the thermal fluid. The SST-400 GEO steam turbine can be deployed in geothermal power plants that operate with superheated direct steam (dry steam) or with saturated steam produced on pressure reduction of the thermal fluid (flash principle). The turbine can also be deployed in the direct or flash steam cycle of combined direct or flash steam/binary systems (flash/binary combined cycle).

The low steam parameters and the aggressive constituents of the thermal fluid sometimes result in extensive corrosion. As a result, these plants require specially adapted steam turbines. The features demanded include special high-grade materials to combat corrosion and to prevent fatigue-related crack formation and fractures. The SST-400 GEO is suitable for live steam temperatures up to 250°C, with steam pressures up to 12 bar absolute, and includes resource- and turbine-stage-specific high-grade materials as well as special features for moisture removal at every stage.

“Geothermal power plants are characterized by special steam parameters, which require a solution specially adapted to meet these technical challenges,” said Werner Altmeyer, Siemens’ sales manager responsible for global turbine sales and marketing. “Our new steam turbine combines Siemens turbine know-how with the wealth of experience accumulated by TurboCare in preventive and corrective maintenance of steam turbines for geothermal power plants.”

For additional information: