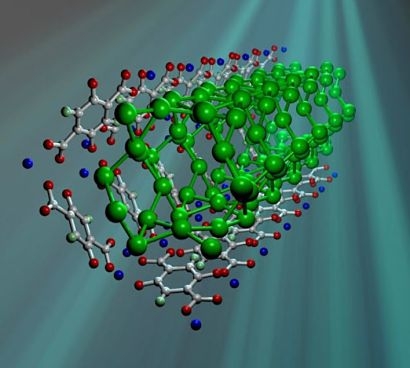

CarbonMeta Technologies is commercialising breakthrough technology from the University of Oxford called ‘microwave catalysis’. The company is making plans to process waste plastic at scale in custom-designed microwave machines which will yield high value products for industry.

One metric ton of plastic mixed with 200 kg of iron powder catalyst can selectively produce enough hydrogen to heat approximately 200 homes, and can yield 900 kg of graphite and carbon nanotubes, which can be used to build battery technology for powering electric vehicles.

Transforming one ton of plastic using the technology can on average take two hours, with the material reaching temperatures of up to 600 degrees Celsius.

The company is forging commercial partnerships to up-scale this technology, including global multi-energy providers in Europe. Its latest initiative is an assessment project in Spain, which will analyse how differing combinations of mixed plastics waste perform in the new process, and how to generate the most substantial yields.

CarbonMeta’s mission is to ‘upcycle’ plastic and construction waste to help address the world’s burgeoning pollution and climate crises. The company’s technology will support the transition to two major sources of sustainable energy – hydrogen for transport or to heat homes and batteries for electric vehicles. Based in Woodinville, Washington, the firm is a developing a global reach predominantly based on this British innovation.

Oxford don Professor Peter Edwards is the brains behind the process, having conducted over two decades of research in environmentally-focused chemistry. His other work includes using carbon dioxide to create aviation fuel and extracting green hydrogen from fossil fuels. He was elected a Fellow of the Royal Society in 1996.

“Our project in Spain is the first step on the road to fully commercialising what is a breakthrough technology” said Lloyd Spencer, CEO of CarbonMeta Technologies. “While a big part of sorting out plastic pollution is simply to stop producing so much plastic, we still need a sustainable process for dealing with what is still manufactured. With US entrepreneurship and investment, British research and European business support, this method of making something clean and useful out of problem plastic has potential global reach.”

Professor Peter Edwards added that the process is a ground-breaking solution to the global challenge of plastics waste.

“It is thrilling for myself and my colleagues to see this technology move out of the limited capacity of a chemistry lab into testing at a genuinely commercial scale” Professor Edwards said. “We want the most robust possible figures on yield, so that we can demonstrate the potential of our microwave catalysis process to place plastics waste as a key contributor both to hydrogen energy and battery technology.”

The results of the European project will be published in the Autumn of 2022, with further commercial partnerships expected to follow with global energy firms who could benefit from the technology.

For additional information: