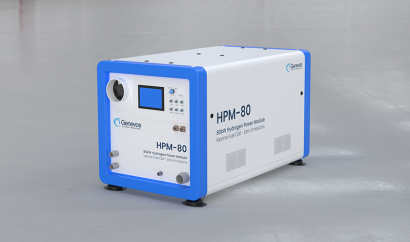

The HPM-80 joins the HPM-15 and HPM-40 marine fuel cell family providing a drop-in solution for decarbonising boats and ships with propulsion systems from 10 kW to 5 MW. The range is in the Type Approval Certification process with the first HPM-80 multi-stacked system to be delivered this summer.

Applicable to a broad range of maritime vessels

Genevos' technology offers a low weight, optimized, and modular solution to meet specific energy requirements of a vessel, delivering 100% clean power and emitting only water as a by-product.

HPM-80s can be stacked to high power to fully decarbonise a diverse range of vessels including ferries, crew transfer vessels, offshore support vessels, tug boats, and even small freighters for short-sea transport.

Alternatively, hybridization can offer a valuable first step towards full decarbonization, and extend the life of existing vessels. A vast range of commercial applications such as service, fishing and patrol boats operate at low speed, where a combustion engine is most inefficient and which can be replaced by fuel cell electric propulsion. Such hybridisation can reduce fuel consumption by over 50%.

Additionally, for existing cargo and cruise ships, the HPM-80s can be used to eliminate emissions in port and at anchor by powering auxiliary vessel systems. This is particularly important in populated coastal areas and maritime cities, in order to reduce toxic NOx and particle emissions.

Practical marine application: HPM-80 features

Weighing in at just 330 kg, the HPM-80 is one third of the weight of an equivalent diesel genset, and has been carefully engineered to minimize the overall weight and energy consumption of a vessel.

Durability and reliability are core to Genevos' marine design philosophy, which led to the development of highly scalable modules. The HPMs are electrically connected in parallel to reach optimal vessel power requirements, with each module protected and controlled to provide independent power, enabling high efficiency and redundancy.

The HPM family uses corrosion-resistant graphite plate technology by integrating Cummins-Hydrogenics high durability (HD-series) stacks, which have been developed and tested for heavy duty applications over the last 20 years.

"Energy security and reliability is crucial for a vessel and is especially important for a professional boat that can reach over 5,000 hrs of use per year. The independent operation of each module provides that all-important redundancy, and the vessel can continue normal operation if one module is shut down or removed for maintenance," explains Phil Sharp, CTO and co-founder at Genevos.

Floor space efficiency is an additional important consideration for any vessel design. The HPM-80 offers a unique solution to mechanically stack the modules vertically, with the lower module bolted directly to the floor. This simplifies system installation and avoids the need of an additional supporting structure.

The HPM-80 will be on display at Hyvolution, stand 6B04, in Paris on the 1st and 2nd of February.