The offer speeds up energy transition by facilitating the use of hydrogen in process industries, without needing to modify all the equipment. Lhyfe will produce and supply green hydrogen and Fives will provide optimised and safe solutions for its use in industrial combustion processes.

In recent years, the combustion of hydrogen, which emits no CO2, has emerged as one of the most promising solutions for reducing the carbon footprint of industrial processes.

For example, a secondary aluminium furnace that today produces 120 tonnes per day using natural gas would tomorrow reduce its annual CO2 emissions by more than 4,000 tonnes with the use of hydrogen.

As recognised experts in their respective fields, Lhyfe and Fives will focus primarily on the metals, glass and cement industries and some selected industrial heating processes and applications in Europe and North America.

Lhyfe is one of the world’s pioneers in the production of green and renewable hydrogen. It produces green and renewable hydrogen through the electrolysis of water, at production units powered by renewable energy. The company’s first site has already been operational since the second half of 2021, and two further sites were inaugurated in 2023. Several other sites are being built or extended across Europe.

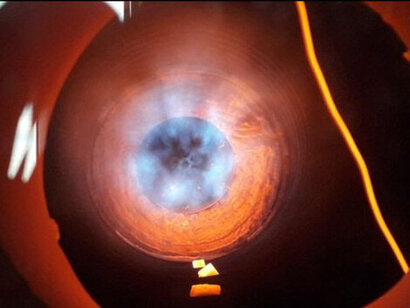

Fives is the international leader in industrial engineering with more than 100 years of expertise in industrial combustion. The group has been a technological leader in hydrogen for over 50 years, developing cutting-edge technologies across the entire value chain. Under the ITAS, North American and Pillard® brands, Fives offers the widest range of hydrogen proven burners available on the market to serve all industries.

“We are in a pivotal period in the industrial sector and in particular in industrial combustion” said Matthieu Guesné, founder and CEO of Lhyfe. “After several years of development, hydrogen solutions are now mature and available on the market regionwide. We are proud and delighted to sign this agreement with a company such as Fives, which is helping to accelerate energy transition in the glass, cement and metals industries, thanks to turnkey solutions for their processes.”

For additional information: