Most water-splitting devices are made of a stack of light-absorbing materials. Each layer absorbs different parts or “wavelengths” of the solar spectrum, ranging from less-energetic wavelengths of infrared light to more-energetic wavelengths of visible or ultraviolet light.

When each layer absorbs light it builds an electrical voltage. These individual voltages combine into one voltage large enough to split water into oxygen and hydrogen fuel. But according to Gideon Segev, a postdoctoral researcher at JCAP in Berkeley Lab’s Chemical Sciences Division and the study’s lead author, the problem with this configuration is that even though silicon solar cells can generate electricity very close to their limit, their high-performance potential is compromised when they are part of a water-splitting device.

“It’s like always running a car in first gear,” said Segev. “This is energy that you could harvest, but because silicon isn’t acting at its maximum power point, most of the excited electrons in the silicon have nowhere to go, so they lose their energy before they are utilized to do useful work.”

So Segev and his co-authors – Jeffrey W. Beeman, a JCAP researcher in Berkeley Lab’s Chemical Sciences Division, and former Berkeley Lab and JCAP researchers Jeffery Greenblatt, who now heads the Bay Area-based technology consultancy Emerging Futures LLC, and Ian Sharp, now a professor of experimental semiconductor physics at the Technical University of Munich in Germany – proposed a surprisingly simple solution to a complex problem.

“We thought, ‘What if we just let the electrons out?’” said Segev.

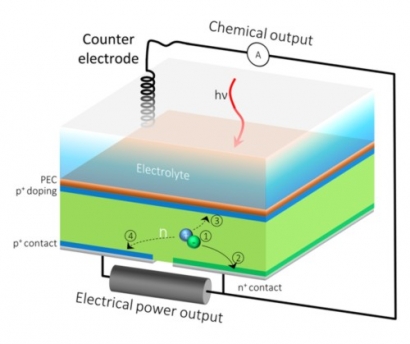

In water-splitting devices, the front surface is usually dedicated to solar fuels production, and the back surface serves as an electrical outlet. To work around the conventional system’s limitations, they added an additional electrical contact to the silicon component’s back surface, resulting in an HPEV device with two contacts in the back instead of just one. The extra back outlet would allow the current to be split into two, so that one part of the current contributes to solar fuels generation, and the rest can be extracted as electrical power.

After running a simulation to predict whether the HPEC would function as designed, they made a prototype to test their theory. “And to our surprise, it worked!” Segev said.

According to their calculations, a conventional solar hydrogen generator based on a combination of bismuth vanadate and silicon will utilize only 6.8 percent of the solar energy striking the cell and store it the form of hydrogen fuel. All the rest is lost.

In contrast, the HPEV cells harvest leftover electrons that do not contribute to fuel generation. These residual electrons are used to generate electrical power, resulting in a dramatic increase in the overall solar energy conversion efficiency. For example, according to the same calculations, the same 6.8 percent of the solar energy can be stored as hydrogen fuel in an HPEV cell made of bismuth vanadate and silicon, and another 13.4 percent of the solar energy can be converted to electricity. This enables a combined efficiency of 20.2 percent, three times better than conventional solar hydrogen cells.

The researchers plan to continue their collaboration so they can look into using the HPEV concept for other applications such as reducing carbon dioxide emissions. “This was truly a group effort where people with a lot of experience were able to contribute,” added Segev. “After a year and a half of working together on a pretty tedious process, it was great to see our experiments finally come together.”

The Joint Center for Artificial Photosynthesis is a DOE Energy Innovation Hub.

The work was supported by the DOE Office of Science.

Illustration:The HPEV cell’s extra back outlet would allow the current to be split into two, so that one part of the current contributes to solar fuels generation, and the rest can be extracted as electrical power. (Credit: Berkeley Lab, JCAP)