“Green” hydrogen production is ideal for long-term energy storage, hydrogen mobility and other applications, making optimal use of renewable energy sources. Based on worldwide leading electrolysis technologies, experts from thyssenkrupp have developed a solution which makes large-scale hydrogen production from electricity economically attractive.

The water electrolysis features a cell design paired with an especially large active cell area of 2.7 m2 . By further optimizing the proven “Zero-Gap” electrolysis technology (leaving virtually no gap between membrane and electrodes), very high efficiencies of more than 82 percent are achieved.

Sami Pelkonen, CEO of the Electrolysis & Polymers Technologies business unit at thyssenkrupp Industrial Solutions, said, “With our water electrolysis process, we have successfully brought a technology to market maturity which is of major significance for the energy transition. We are now able to offer our customers a wealth of sustainable solutions which will help to bridge the gap between renewable energy production and consumption. Green hydrogen as a clean, CO2-free starting point can be used in a variety of ways: for energy storage, mobility, and the production of sustainable chemicals.”

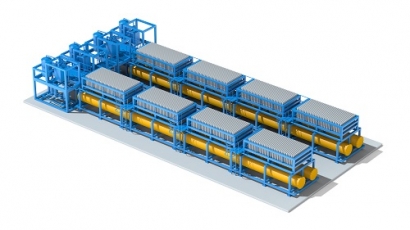

The thyssenkrupp technology is available in pre-fabricated, skid mounted standard modules. They easily add up to the desired project size, potentially into the hundreds of megawatt range.

“Based on decades of experience in developing and building electrolysis plants, we have designed our product to meet our client’s most important demands: easy to deliver and install, highly efficient, with minimized investment and operation cost. And we have an industrial-scale supply chain of 600 MW per year already in place”, stated Roland Käppner, Head of Energy Storage and Hydrogen at thyssenkrupp Uhde Chlorine Engineers.

Within the Carbon2Chem® project, one of the global flagship projects for carbon-neutral value chains, the advanced alkaline water electrolysis by thyssenkrupp was already commissioned successfully. It will provide the necessary hydrogen for producing chemicals from steel plant flue gas.

When produced from renewable energy, hydrogen can make the production of key chemicals sustainable. One good example is “green” ammonia: With the water electrolysis technology and its world-class ammonia process, thyssenkrupp can deliver integrated plants which can produce ammonia from nothing but water, air and sunlight or wind. The ammonia can be further processed into fertilizers.

As a specialist in chemical plant engineering and construction, thyssenkrupp can realize additional value chains, e.g. for “green” methanol, which can enable carbon recycling to generate sustainable fuel. Further “power-to-gas” solutions include methanation for the production of synthetic natural gas (SNG). As the starting point for all these solutions, water electrolysis by thyssenkrupp can help to convert today's carbon-based industry into a more sustainable, climate-friendly one.