Prinz led a team of engineers that created a solid oxide fuel cell capable of delivering the most power-per-square inch yet developed, at record-low temperatures.

The U.S. Department of Energy is interested in solid oxide fuel cells as clean energy sources for the future. Using domestic fuel sources, these fuel cells could support or replace large-scale, oil-driven energy production. For this to happen, the cells must be made to run more efficiently and at lower temperatures.

The Stanford team made strides towards this goal and reported its milestone in a recent edition of Nano Letters. The journal Science also featured the work as an Editors’ Choice.

This record-setting performance is the culmination of more than a decade’s worth of research performed by several generations of students. Their work began in 1999, when the Honda Motor Company approached Prinz with a straightforward request.

“They wanted better fuel cells,” he recalls. Solid oxide fuel cells are also strong candidates for auxiliary power sources in automobiles, according to the DOE.

Solid oxide fuel cells are compartmentalized, stackable units or cells. Each cell is made up of three components: a fuel, an oxygen supply and a special membrane that facilitates an energy-producing reaction.

The fuel, typically hydrogen or natural gas, is supplied by a canister or tank. Oxygen comes from the air. Separating the fuel from the oxygen is a membrane made of a solid oxide material. That membrane transports negatively charged oxygen ions from the oxygen side to the fuel side of the cell.

The membrane is lightly coated with platinum particles. On the oxygen side of the membrane, these particles help break neutral oxygen molecules into negatively charged oxygen ions. The solid oxide material shuttles these ions through the membrane to the fuel side. Once there, these ions react with the fuel, liberating electrons, the particle basis of electricity. Freed electrons can then be wired into a device such as a light bulb, a smartphone or a car.

The Stanford researchers sought to solve a burning problem in current fuel cell technology. Ions move faster at higher temperatures, meaning the devices operate more efficiently as they grow hotter. Current cells typically run at temperatures well above 500 degrees Celsius, or roughly 900 degrees Fahrenheit. That’s hot enough to melt the zinc in pennies.

An external energy source, such as a furnace or a battery-powered heater, can be used to supply an initial burst of heat to get the ions moving through the membrane. Once the oxygen and fuel react, they generate heat that can be recycled back into the fuel cell to keep it running. Lowering the temperature at which a fuel cell operates would reduce the amount of energy needed to maintain sufficiently high reaction rates and sufficiently fast ion flow. It would also expand the list of materials that could be used in fuel cell construction, allowing for less expensive and more robust designs.

But there has been a tradeoff. Lower temperatures have also meant slower reaction rates and slower ion transport. Prinz and his team wanted to make their fuel cells run cooler without letting slow-moving ions sap the efficiency of the system. The key was redesigning the solid oxide membrane to conduct oxygen ions more effectively at lower temperatures.

“Oxygen is the bottleneck,” says Jihwan An, a Stanford post-doctoral scholar and first author of the Nano Letters article. “That’s why most of our efforts and innovations were focused on the oxygen side of the membrane.”

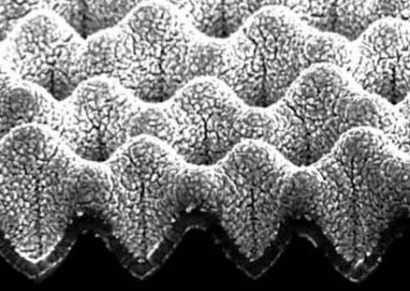

Conventional solid oxide fuel cell membranes are flat. Flat membranes, while easier to fabricate, are not the most effective use of space, the Stanford researchers decided.

So they made a series of improvements to the critical solid oxide membrane.

First, they made their membranes bumpy to increase the surface area that could shuttle oxygen ions. Then they made these bumpy surfaces bristle like sandpaper to further increase the potential points of contact between the solid oxide and the charged oxygen. Another improvement involved fabricating extraordinarily thin membranes to make it easier for ions to cross over to the fuel side. At a thickness of 60 nanometers, the membrane described in Nano Letters is roughly 200 times thinner than cellophane.

The Stanford engineers added yet another feature to improve the efficiency of their fuel cell. They coated their membrane with a new catalyst designed to help usher ions into the membrane.

Finally they gave this catalytic layer its own nano-bristles for the same reason they roughed up the surface of the membrane: to give oxygen ions more opportunities to become absorbed into the reaction.

Other authors on the report include Stanford materials science and engineering graduate student Joonsuk Park; Consulting Professor of Materials Science and Engineering Turgut Gür; and corresponding author Professor Young-Beom Kim of Hanyang University in South Korea. Gür is also the Executive Director of Stanford’s DOE-EFRC Center for Nanostructuring for Efficient Energy Conversion.

Prinz believes that their new techniques could help advance progress toward further lowering the operating temperatures of solid oxide fuel cells without compromising performance. These are pivotal steps for solid oxide fuel cells toward becoming commercial power supplies in the future.

“We’re interested in the extent to which nature can be finessed to advance energy efficiency,” Prinz said.

Photo caption: This bristly, bumpy membrane designed by Stanford engineers is the centerpiece of the most powerful, coolest-running solid oxide fuel cell of its size. (Reprinted with permission from An, J.; Kim, Y.-B.; Park, J.; Gür, T.M.; Prinz, F.B. Three-Dimensional Nanostructured Bilayer Solid Oxide Fuel Cell with 1.3 W/cm2 at 450 ℃. Nano Lett. 2013,13, 4551-4555. Copyright 2013 American Chemical Society.)

For additional information: