Midsummer is a leading Swedish developer and manufacturer of thin film CIGS solar cells. Recently, by a joint project with Prof. Yang, they have demonstrated a 4-terminal perovskite-CIGS tandem solar cell. It is based on a perovskite top cell that has been optimized for integration with Midsummer’s CIGS cells that are utilized in their commercial suite of BIPV products.

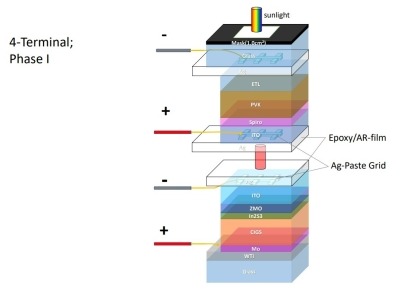

The cell has shown an efficiency of 24.9% as a 4-terminal device architecture. It consists of a top layer of wide bandgap perovskite cell and a bottom layer of the CIGS cell. The research continues with the aim of a two-terminal perovskite-CIGS cell which will render this particular solar cell highly competitive and suitable for mass production.

This work shows the feasibility of building a tandem cell on a breakthrough production proven process developed at Midsummer and using the Midsummer DUO machine. The DUO production system developed by Midsummer is able to provide high performance CIGS solar cells with dimensions of 156 mm x 156 mm on a flexible stainless steel substrate. This form factor is ideally suited for subsequent processing of perovskite films on the company’s current BIPV product suite (SLIM; WAVE; and BOLD).

“We feel fortunate to be working with Professor Yang’s group at UCLA which has demonstrated key advances in perovskites,” said Leon Chiu, President, Pioneer Materials, Inc. which is a key supplier for compound sputtering targets used in Midsummer’s novel processing for CIGS on stainless steel.

“Integrating Midsummer’s production proven CIGS processing with Yang’s Lab tailored perovskite shows a clear path toward expanding the reach of BIPV by improving efficiency and lowering costs.”

“Perovskite-CIGS tandem cells have great future potential and Midsummer’s solar panel design has by far the best conditions for building a commercial product for this type of solar panel, e.g since it contains a diode between each solar cell,” comments Sven Lindström, CEO, Midsummer.