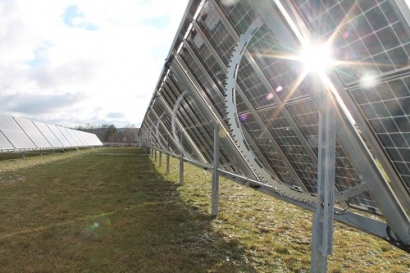

The Schletter Group’s 2018 tracking system has been optimized for bifacial modules. The reverse side of the module tables was adjusted so that the modules can be installed without shading, i. e. without any disturbing metal struts or the like. Unlike most single-axis tracking systems, the Schletter Tracker does not require a central torque tube at the pivot point of the table. This allows for greater flexibility when it comes to module arrangement and the use of bifacial modules in particular.

“This does not change the key design advantage of the Schletter Tracker,” said Christian Salzeder, CSO Tracker at Schletter.

The system works with a patented mechanical self-locking system, i. e. there is a mechanical locking element on each post, which locks automatically if the row is not moved. This eliminates all wind-induced vibrations (so-called galloping effect) for the entire row. When in the resting position, the system therefore has the characteristics and resilience of a fixed installation, suitable for wind speeds of up to 260 km/h.

The upper assembly group with the drive unit is delivered pre-assembled. This means that the system can be installed almost as quickly as a fixed installation. The Schletter Tracker is already used with bifacial modules at a project in Bavaria.

Scheletter will also showcase the new and improved generation of roof hooks for the Eco and Rapid 2+ series. The company claims they provide savings in installation time and costs. The roof hooks are welded in one piece and come in 6 or 8 mm bar thickness. They are made of the high-strength steel grade S700MC in accordance with EN 10149-2: 2013-12 and have already been granted European Technical Approval (ETA). Their strength, which has been significantly increased compared to the predecessors, meets the requirements for mechanical strength, stability, structural integrity and durability stipulated in EU Regulation 305/2011.

The Schletter Group will be at Intersolar Europe, Hall A3, Booth 140.