“We have radically redesigned the third generation of our globally implemented FS open area system to optimize yields,” says Florian Roos, CEO of the Schletter Group.

The new FS Gen 3 uses less material per kilowatt output – with the same or even higher load-bearing capacity. In addition, the system is easier to assemble thanks to the targeted optimization of individual components. “With our FS Gen 3, customers save time and money during the installation and optimize their return on investment,” Roos added.

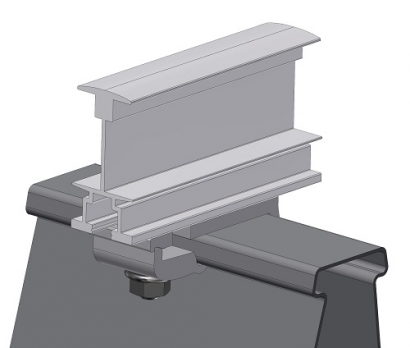

For the pile driven foundations, girders and purlins of the FS Gen 3, Schletter is using high-tensile steel, which is usually only used in the automotive and mechanical engineering industry. At the same time, the Schletter engineers have fundamentally redesigned the geometry of the purlins: instead of following a Z profile, the cross section of the purlins is formed as a downward opening, symmetrical trapezium.

The new shape in combination with the new material significantly increases the load capacity of the purlins. The new purlins can support spans of up to 6.5 meters, i.e. around 20 percent more than the previous generation. This means that with the FS Gen 3, more PV capacity can be installed on fewer supports.

The purlins also serve as a cable tray. With the new FS Gen 3, string cables are fed through the purlins and thus protected against wind and weather as well as UV radiation. This renders the cumbersome and expensive application of cable ties obsolete.

In order to reduce the time needed to assemble the system, Schletter has also fully optimized and aligned its individual components. Most connections are based on clamps. The construction is so designed that no on-site drilling or pre-punching of holes is necessary.

In order to simplify and accelerate the mounting of modules, the Schletter engineers have developed a new rafter lay-in system. The modules are simply pushed in from below between the tilted rafters and then fastened with a slip guard.

The rafter assembly can be used for frames of 30, 35 and 40mm in thickness. Frameless modules or other module strengths can still be fastened with clamp-based rafter systems.

The Schletter Group will be in booth 5407 at SPI.