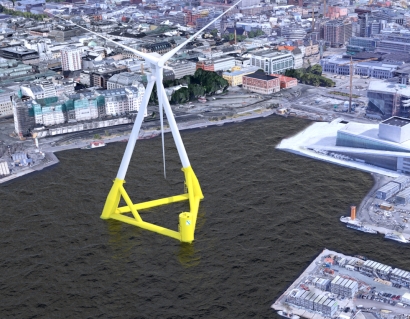

BRUNEL is a semi-submersible structure with proprietary rights, designed for harsh north-sea conditions, with a modular design based on steel tubulars, as known from monopiles and wind towers. BRUNEL has a comprehensive focus on serial and automized mass production to enable manufacturing and assembly at a volume needed for the floating giga parks.

The modular design enables BRUNEL to leverage the existing global supply chain and helps create a sustainable industry.

“The design of BRUNEL is based on a simple, yet challenging design philosophy: to see if we can build a foundation based on generic steel tubulars and hence enable manufacturing at commercial scale. This radical focus on commercial requirements, while at the same time attending to excellence on all technical parameters, will allow the floating offshore wind industry to realize its enormous potential," said Sofie Olsen Jebsen, CEO, Fred. Olsen 1848

BRUNEL enters the market at an advanced technological stage, with a final tank test successfully completed at SINTEF Ocean in February 2022. In parallel, BRUNEL successfully received DNV’s statement of feasibility in April 2022. With the tank test and DNV statement of feasibility, BRUNEL has completed a significant milestone to reach Technological Readiness Level 4 (TRL 4).

Fred. Olsen 1848 is determined to make BRUNEL available for commercial use as quickly as possible. Working with SINTEF Ocean, a Physical-Numerical Validation Approach will be applied to demonstrate and qualify BRUNEL according to standard procedures from Oil & Gas and maritime, i.e., exempting the need for piloting and full-scale demonstration.

Through this process, BRUNEL will reach TRL 8 at an accelerated pace and will be ready for commercial application within 3 years. Fred. Olsen 1848 will involve leading engineering and fabrication specialists in the process to ensure the requirements of the industry are being addressed; both technically and commercially.

Fred. Olsen 1848 is in close co-operation with customers and other partners to position BRUNEL as the floater of choice for the large scale floating offshore wind farms to be built.

BRUNEL harnesses the advantage of sourcing and procurement from an existing global supply chain. This will de-risk the floating offshore wind projects and offer a high degree of flexibility to maximize the local content footprint, which again will support individual countries’ ability to grow the floating offshore wind industry both domestically and internationally.

BRUNEL also offers a wide range of geographical deployment areas, and scalability to fit the next generation of wind turbines without noticeable changes to the design. In addition, Brunel has a low draft implying flexibility in ports. All this allows for the industry to drive down cost by the use of BRUNEL and to continue to apply optimizations into the supply chain with a view to accelerate the industrialization of floating offshore wind.

An instrumental part of BRUNEL has been to reduce the maintenance requirements, and Fred.Olsen 1848 has Floating Maintenance Solutions on the way to the market to enhance operations and maintenance activities, including component exchange, at the floating offshore wind site. Avoiding having to tow the foundations to shore for component exchange, will further drive down the cost of LCOE.

“Brunel is designed for the next generation of wind turbines. With its low LCOE and ability for serial and mass production, we believe the Brunel to be a game-changer that can unlock the potential of floating offshore wind,” Jebsen said.