The system has been designed to dramatically reduce the cost of offshore wind energy in an industry that has often been characterised thus far by rising costs and dependency on high feed-in tariffs. The aim of the new system is to reduce the Levelised Cost of Energy (LCOE) from its current level of 0.15 to 0.20 euros per kilowatt hour to below 0.09 euros within the next five years.

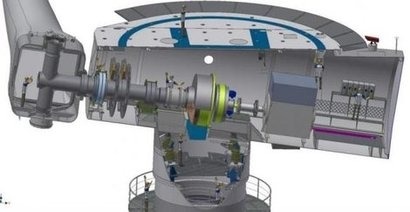

The Seawind 6 wind turbine has been designed to produce low cost energy via a float-to-fix installation solution for shallow waters. It incorporates a simple design with no pitch control mechanism and which is aimed at facilitating easier operations and maintenance (O&M). The variable speed wind turbine has a teetering hinge incorporating an elastic coupling of the rotor to the shaft. Power production is achieved by turning the turbine head into or out of the wind (yawing), rather than turning the blades around their axis (pitching). In this way, Seawind 6 eliminates pitch control – the major source of failure for three-bladed wind turbines. The yawing action is governed by four small drivers through parallel hydraulic closed circuits pressurised by pumps that are mechanically driven by the gearbox. The teetering hinge enables fast yawing for power control.

The system’s support structures are designed to allow complete assembly at a pier. This is facilitated by the two-bladed, almost mono-dimensional rotor and requires no excessively large handling area. A piled tetrapod construction made of bolted parts forms the support structure for shallow waters. This can be assembled vertically at a pier by a crane on a semi-submersible barge and completed by arranging relevant pile driving devices or suction piles inside the legs of the tetrapod piles.

For deep waters, the spar buoy support structure is assembled by two cranes, horizontally, onto the water surface at the pier. The nacelle is then mounted on the horizontal spar buoy in the water, followed by the rotor with the two blades directed along the spar. The complete system is then towed out to sea with simple tug boats and installed at the site by ballasting the bottom section of the spar. The spar is then turned slowly around a horizontal axis close to the sea surface, like a hinge, through a combination of water ballast, buoyancy, and weight of the system.

Seawind was incorporated in 2014 in the Netherlands and is led by CEO Martin Jakubowski who founded Good Energy PLC in 1997 and Blue H Group Technologies among others. Seawind recently launched a crowdfunding campaign with the aim of raising 250,000 euros in capital. The company is currently approaching completion of the demonstration model design and installation method and intends to apply for certification of the turbine and installation method from TUV Nord. The money raised by the crowdfunding campaign will help to further develop the demonstration model, complete independent verification and consolidate the company’s intellectual property. Seawind intends to license its technology to regional licensees for 5 million euros per region with a royalty for each offshore wind turbine installed and a performance fee from the revenues generated by the turbines during the lifetime of the offshore wind farm.

Image: Seawind

For additional information: