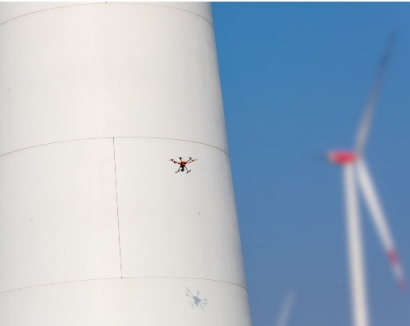

The entire concrete tower is photographed by drone; experienced TÜV NORD experts later evaluate the images. In the medium term, an automated image recognition system is also to be used, which will pre-sort images with conspicuous features on the basis of extensive training data so that the experts can view and evaluate the images in an even more targeted manner.

"Initially small cracks and spalling can later lead to critical damage in the concrete structure. That is why it is important to assess any anomalies on the tower before the end of the warranty period so that they can be repaired," explains wind energy expert Michael Lange.

He is responsible for remote inspection projects for renewable energies at TÜV NORD. Using drones for this inspection now simplifies image capture and also means greater occupational safety, as no additional skilled personnel with rope access technology have to be deployed, says Lange.

"We are also working on a system that will allow the drone to fly autonomously up the tower, so that jobs can be completed in less time."

Alexander Ohff, Executive Vice President of the Renewables Segment at TÜV NORD, finds this a good example of the ongoing innovation projects.

"We use digital technologies such as drones or new software solutions to make services more efficient or safer. Pilot projects evaluate the benefits in practice."

Using the drone-based inspection, 34 of the manufacturer's wind turbines have already been assessed this year. The results have been validated. Now, the procedure is being extended to additional sites. Talks are underway with other manufacturers and wind farm operators.